Ferro Silicon Magnesium

Introduction

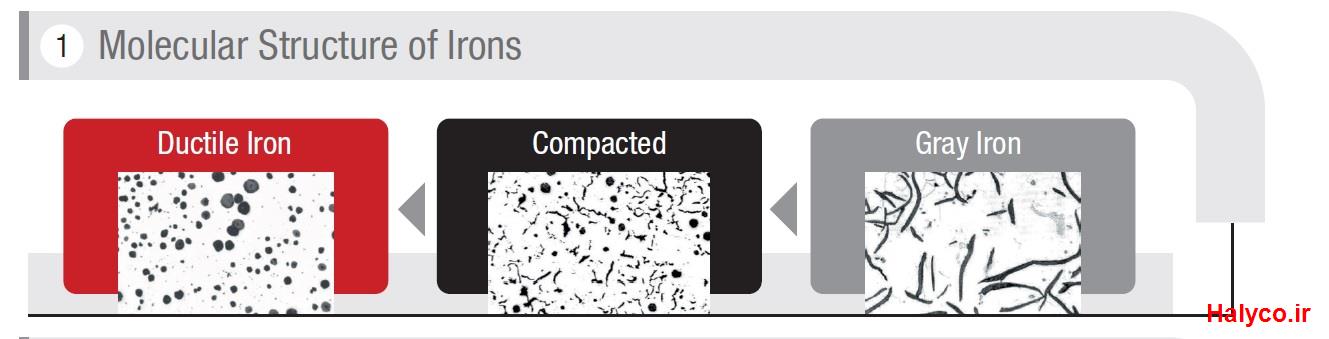

Ferrosilicon magnesium (FeSiMg) is a basic foundry alloy used for the production of ductile cast iron. Magnesium content plays an important role in the produced alloy grades from dolomite ore. Magnesium treatment is an important step in the production of ductile (DI) iron and compacted (CGI) iron. The primary purpose of introducing magnesium to the molten metal is the formation of spherical graphite, also called spheroids or nodules. These graphite shapes, when produced correctly, are essential in providing the iron with the desired mechanical / Chemical properties.

• Improved microstructure and mechanical properties

• Improve the nucleation state of the molten metal

Applications

Ferrosilicon magnesium alloy is used to produce all types of ductile iron castings. It is added to the molten iron to produce a structure containing graphite in nodular or spheroidal form. This form minimizes the weakening and embrittling effect of graphite on the metal matrix resulting the production of cast iron with better machinability, toughness and tensile properties. Ferrosilicon magnesium consists mainly of magnesium silicide combined with the silicide of iron, calcium and rare earth (RE) metals. Magnesium treatment have been applied to

• Adjusting iron composition: Ductile (DI) iron grade

• Consistent casting quality

• Achieving process stability

• Achieving a proper chemical composition

of oxygen and sulfur.

Cataloge

MSDS